Key Takeaways

- Learn the essentials of pipeline safety and how it impacts overall efficiency.

- Understand the importance of regular maintenance and monitoring.

- Discover real-life examples and data-driven insights on pipeline management.

Table of Contents

- Introduction to Pipeline Safety

- The Importance of Regular Maintenance

- Effective Monitoring Strategies

- Data-Driven Insights on Pipeline Management

- Real-Life Examples of Pipeline Safety

- Conclusion

Introduction to Pipeline Safety

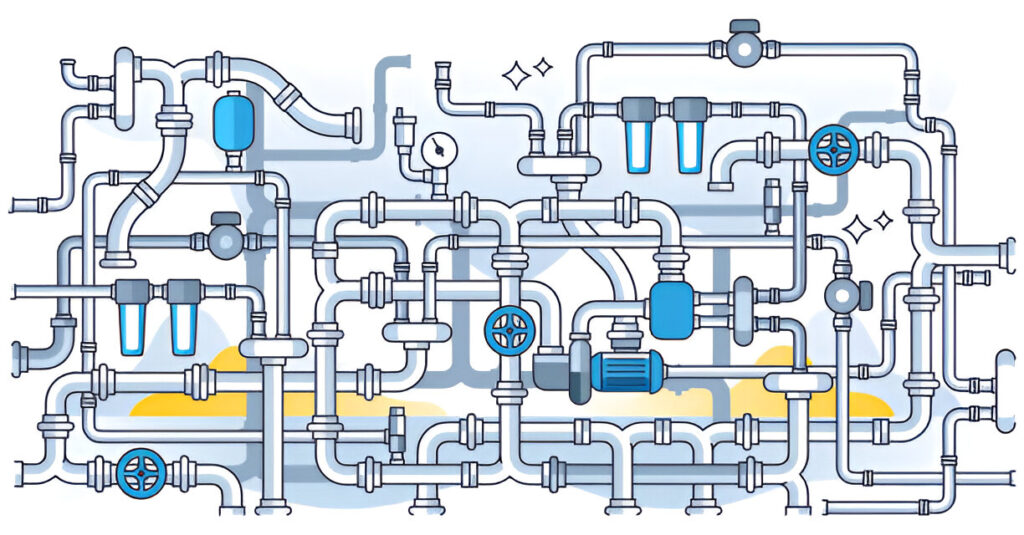

Pipeline safety is a critical aspect of any infrastructure project involving transporting liquids and gases. It ensures not only the longevity of the pipeline but also protects the environment and public health. A safe pipeline operates more efficiently, reducing the risk of accidents that could lead to costly repairs and significant losses. Quality pipeline-pigging products can significantly contribute to these safety measures by maintaining cleanliness and operational efficiency.

Safety aspects extend beyond the immediate protection of the pipeline itself. They encompass environmental conservation, as leaks or bursts can lead to soil and water contamination, affecting ecosystems and, in some cases, human populations. Moreover, the economic implications of a pipeline failure include the direct costs of repair and lost product, potential fines, and a damaged reputation for the company involved. Adequate safety measures are thus integral to the sustainability of pipeline operations.

The Importance of Regular Maintenance

Regular maintenance prevents pipeline failures and ensures continuous, efficient operation. Maintenance involves a combination of scheduled inspections, cleaning, and necessary repairs. Potential problems such as corrosion, mechanical damage, or blockages can be identified and addressed during inspections before they escalate. Maintenance activities not only extend the lifespan of the pipeline but also enhance its safety and performance. High-qualit pipeline pigging products effectively ensure thorough cleaning and maintenance, removing deposits and debris that could obstruct flow or cause damage.

The benefits of regular maintenance are manifold. For instance, proactive maintenance helps in detecting corrosion early, which, if left unchecked, could weaken the pipeline’s structure. Additionally, regular cleaning prevents the build-up of paraffin and other substances that can reduce pipeline capacity. An EPA report emphasizes the role of proactive maintenance in mitigating environmental risks, highlighting that well-maintained pipelines are less likely to rupture, thus preventing spills and leaks that could harm the environment.

Effective Monitoring Strategies

Implementing robust monitoring strategies is essential for the early detection of potential issues within a pipeline system. Monitoring involves using advanced technologies and tools such as sensors, drones, and smart software solutions to provide real-time data on the pipeline’s condition. These tools can detect leaks, corrosion, and any other anomalies promptly, enabling swift corrective actions before a minor issue becomes a significant problem. According to PHMSA, pipeline incidents can have profound environmental, economic, and health implications, highlighting the importance of stringent safety protocols.

The effectiveness of a monitoring strategy lies in its comprehensiveness. For example, sensors placed at strategic points along the pipeline can continuously measure pressure, temperature, and flow rates, alerting operators to deviations from the norm. Drones equipped with thermal imaging cameras can fly over the pipeline, identifying areas of heat loss that may indicate a leak. A detailed monitoring plan is vital to pipeline safety and efficiency and to quickly identify and address potential threats.

Data-Driven Insights on Pipeline Management

Leveraging data analytics in pipeline management provides valuable insights that can enhance decision-making processes. Data from various monitoring tools can be analyzed to identify trends and potential risks. This insight allows for more informed maintenance and operational strategies, prioritizing areas that require immediate attention and planning long-term improvements.

Studies have shown that data-driven management can significantly reduce the incidence of pipeline failures. By analyzing patterns and correlations within the data, pipeline managers can predict potential problems before they occur. This proactive approach helps allocate resources more effectively, ensuring that maintenance efforts are timely and targeted to the most critical areas. As data analytics technology advances, its role in pipeline management will become even more prominent, leading to safer and more efficient operations.

Real-Life Examples of Pipeline Safety

Real-world examples demonstrate the importance of pipeline safety measures. For instance, the Alaska Pipeline has employed rigorous maintenance and monitoring protocols to maintain its integrity. This pipeline has advanced monitoring tools and is subject to regular inspections and maintenance schedules. Their proactive approach to using technologies and maintenance practices is a model for other pipeline projects worldwide.

The Alaska Pipeline’s success is attributed to a comprehensive safety strategy encompassing regular maintenance and advanced monitoring technologies. For example, they utilize smart pigging devices for regular internal inspections, ensuring the pipeline remains free of obstructions and damage. Such real-life examples underscore the effectiveness of rigorous safety protocols and the benefits of investing in the latest technologies and best practices in pipeline management.

Conclusion

Ensuring pipeline safety and efficiency is a multi-faceted effort that requires diligent maintenance, advanced monitoring strategies, and data-driven insights. By integrating these elements and learning from real-life examples, pipeline operators can significantly enhance the reliability and safety of their infrastructure. Ongoing investment in quality products and cutting-edge technologies will continue to improve pipeline safety and operational efficiency, safeguarding the environment and public health.