Table of Contents

- Introduction to Gas Line Maintenance

- The Importance of Regular Inspections

- Common Gas Line Issues

- Safety Precautions for Gas Line Maintenance

- Tips for Efficient Gas Line Servicing

- Innovations in Gas Line Technology

- Frequently Asked Questions About Gas Line Maintenance

- Conclusion: Keeping Your Gas Lines Safe

Introduction to Gas Line Maintenance

Gas lines are essential components within residential and commercial settings, often operating silently in the background to supply the energy necessary for various tasks, from cooking meals to heating water. These pipelines are structured for durability, yet they demand a keen eye for maintenance to ensure they function optimally. One of the preventive approaches that stands out is the emphasis on gas line service Calvert County, MD, where the nuances of regular maintenance are highlighted. This service approach centers around ensuring pipelines remain safe, productive, and free from potential hazards that could stem from ignored routine checks. As our reliance on these pipelines increases with technological advancements and urbanization, their upkeep has never been more critical.

The Importance of Regular Inspections

The significance of regular gas line inspections extends beyond mere routine checks. They are foundational to foreseeing and forestalling potential disasters that arise from leaks and wear. Gas leaks are notorious for their ability to cause significant harm, ranging from respiratory issues to catastrophic explosions. Hence, the need for regular checks cannot be overstated. These inspections offer a comprehensive view of the infrastructure, allowing technicians to detect weaknesses such as wear, corrosion, or blockages at an early stage. By adopting a proactive stance through consistent evaluations, property owners and facility managers can circumvent exorbitant repair costs and ensure all occupants’ well-being.

Common Gas Line Issues

Several challenges plague gas line systems, with corrosion, blockages, and leaks being the forerunners. Corrosion, frequently driven by external environmental factors such as moisture and saline conditions, gradually degrades the material integrity of pipelines. On the other hand, blockages may occur due to the accumulation of particulate matter or even the encroachment of tiny pests and debris. These obstructions impede the efficient gas flow, leading to increased pressure and potential leaks. Leaks are perilous as they can go unnoticed for extended periods, leading to severe consequences if ignited. Addressing these common issues requires diligence and a well-rounded maintenance strategy that integrates regular monitoring and timely interventions.

Safety Precautions for Gas Line Maintenance

Regarding gas line maintenance, safety is not just a priority; it’s a prerequisite. Ensuring a safe environment during maintenance involves adhering to stringent guidelines and employing best practices. Technicians should operate in well-ventilated areas, initially verify the presence of gas using detect tools, and ensure no ignition sources are nearby. Moreover, cutting-edge techniques are now replacing traditional methods to enhance safety standards during maintenance, thus reducing the potential for mishaps. Professional oversight is also crucial to ensure all safety measures are meticulously observed, particularly for complex repairs.

Tips for Efficient Gas Line Servicing

Achieving efficiency in gas line servicing involves a strategic approach that embraces modern tools, expert guidance, and diligent record-keeping. Maintaining a well-documented log of all past maintenance checks and inspections for homeowners and facility managers can significantly enhance servicing efficacy. It’s advisable to capitalize on seasonal maintenance schedules, preferably during off-peak times, to ensure minimal disruption to household or business activities. Collaborating with certified professionals to leverage high-tech diagnostic tools also boosts the accuracy and speed of identifying anomalies within the system. Furthermore, understanding the essential operation of your gas lines can aid in recognizing early warning signs, empowering you to act swiftly before issues escalate.

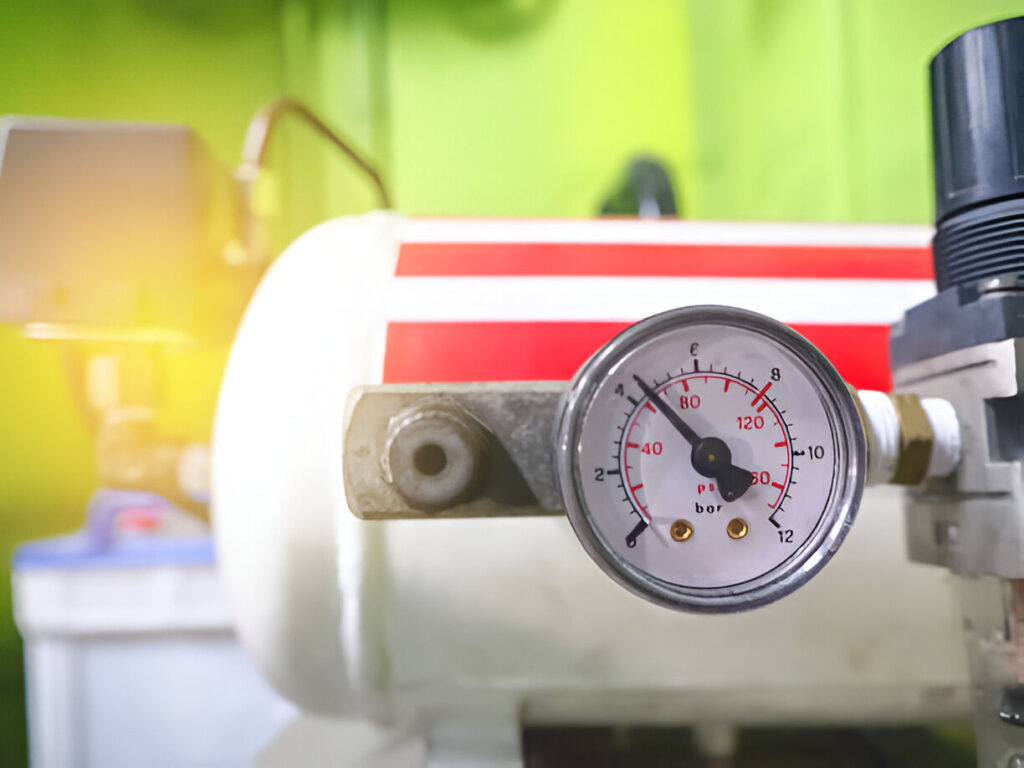

Innovations in Gas Line Technology

Technology continues to evolve, offering groundbreaking solutions that redefine efficiency and safety in gas line maintenance. Recent innovations include smart sensors and IoT devices capable of real-time monitoring, thus facilitating immediate alerts on system irregularities such as pressure drops or leaks. These devices provide invaluable data, enabling property managers and technicians to make informed decisions quickly. Furthermore, progress in materials science has resulted in the creation of stronger pipelines resistant to corrosion and various environmental pressures. Embracing these technologies enhances the lifespan of gas lines and significantly reduces the likelihood of unforeseen failures, making gas line systems more reliable than ever.

Frequently Asked Questions About Gas Line Maintenance

The complexities of gas line systems often lead to numerous questions among users. Here, we address some frequently asked questions to alleviate concerns and provide clarity:

- How often should gas lines be inspected? – Ideally, every year or more frequently if the system is aged or showing signs of wear.

- What are the indications of a gas leak? – Signs include a strong sulfuric odor similar to rotten eggs, unusual hissing noises, or persistent dead spots on vegetation above pipelines.

- Is it safe to undertake gas line repairs oneself? – While knowledgeable individuals can attempt minor checks, certified professionals should always handle significant repairs to ensure safety and compliance with regulations.

Conclusion: Keeping Your Gas Lines Safe

In summation, the essence of gas line maintenance lies in the synergy of regular inspections, adherence to safety protocols, and an openness to technological innovations. Engaging with professional service ensures these elements are harmoniously executed, safeguarding both life and property. By remaining informed and proactive, stakeholders can uphold the integrity of their gas line systems, guaranteeing peace of mind and uninterrupted functionality.